Stay wires play an important role in supporting overhead power lines. It provides great stability and resilience to the infrastructure. With different stay wires available, each of them is designed to meet specific requirements, and understanding the differences is essential for selecting the right one for the job.

In this blog, IAC electricals, a manufacturer of hardware, fittings and accessories in India will dive deeper into the world of stay wires, exploring different types, followed by their unique characters and their applications in various industries.

Types Of Different Stay Wires

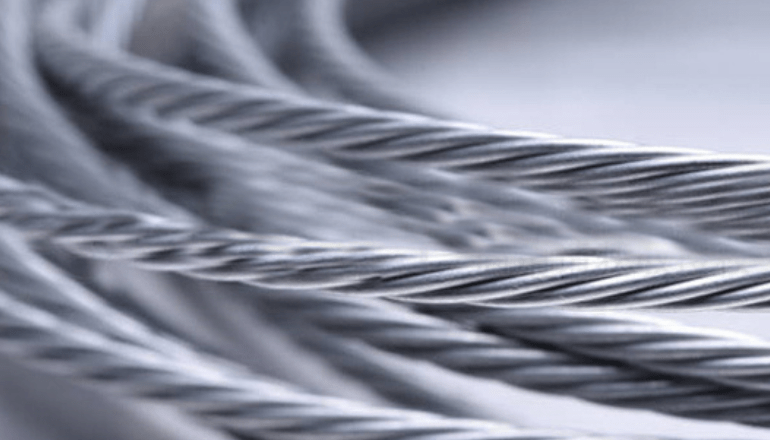

Stay wires are very important components in line construction. It provides stability, support, and resilience. There are different types of stay wires like galvanized wires that offer durability and corrosion resistance, making them important for outdoor applications. Aluminum wires combine lightweight design with excellent conductivity.

Stainless wires offer superior corrosion resistance and copper-clad steel provides high conductivity. Below are the types of stay wires explained in detail:

- Galvanized Stay Wires

Galvanized stay wires are among the most common types used in the line of construction. These types of wires are coated with a layer of zinc through galvanization, which helps protect them from corrosion and rust.

Galvanized stay wires are known for their durability and longevity, making them ideal for outdoor applications where exposure to harsh weather conditions is a concerning factor.

They are used very commonly in electrical transmission and distribution lines, telecommunication towers, and fencing systems.

- Aluminum Stay Wires

Aluminum stay wires provide several advantages over traditional galvanized wires. Lightweight yet very strong, these types of wires are corrosion-resistant and have excellent electrical conductivity. It also makes them suitable for use in electrical transmission and distribution systems. Even aluminum stay wires are very easy to install and maintain, reducing the labor costs and downtime associated with maintenance activities.

They are commonly used in overhead power lines, telecommunications infrastructure, and aerial cable installations. Stay wire accessories also make the usage of the wires correct.

- Stainless Steel Stay Wires

Being one of the leading dealers of ab cable fittings, ground wire accessories, stay wire accessories, and many others, this is a very popular type of stay wire. Stainless steel stay wires are appreciated for their exceptional corrosion resistance and strength. This makes them ideal for demanding applications in harsh environments.

These wires are made with the help of high-quality stainless steel alloys which offer super resistance to corrosion and rust. Stainless steel wires are used mainly in marine environments, coastal areas, and industrial facilities where exposure to corrosive chemicals is a concern. They are also used in architectural and structural applications where aesthetics are paramount.

- Copper-Clad Steel Stay Wires

Copper-clad steel stay wires combine the conductivity of copper with the strength and durability of steel. This type of stay wire offers a versatile solution for different applications.

These wires feature a steel core coated with a layer of good conductivity of copper, providing excellent electrical performance by maintaining structural integrity.

Among different stay wires, this type of wire is commonly used in grounding systems, lightning protection systems, and electrical grounding applications.

These types of wires are also used in telecommunications infrastructure and radio frequency applications where conductivity is important.

- High Tensile Stay Wires

Insulator fittings manufacturers in India prefer this type of stay wires for construction purposes. These are used to withstand high levels of tension and stress without deforming or breaking. It is made from high-strength steel alloys such as carbon steel or alloy steel. It undergoes special treatment processes to enhance its mechanical properties.

High tensile stay wires are used in applications where extreme tension loads are expected. These are used in power line construction, suspension bridge cables, and guy wires for tall structures. They offer super strength, durability, and performance, making them a reliable choice for complex infrastructure projects.

Final Words

Different Stay Wires are important components in overhead line construction, providing stability, support, and sustainability to the infrastructure.

By gaining knowledge of different types of stay wires available and their uncommon characteristics, engineers, and designers can opt for the most suitable option for their particular requirements.

Whether it is galvanized, aluminum, stainless steel, or copper-clad steel, each of them offers different advantages if you choose IAC Electricals. Proper selection with IAC Electricals plays a vital role in ensuring the reliability and longevity of overhead power lines and structural systems.