The company owns sufficient area for its manufacturing processes. The areas are kept clean with clear demarcation of gangways, drive ways, Manufacturing lines and storage. The factory is well ventilated with HSE been maintained as a practice. Regular drills are conducted keep the people aware of the hazards and the mitigation thereof. The factory units...

IAC products are given the required quality packing for air/road/sea transport. Sea worthy packing with fumigation of containers is done for export supplies. This ensures safe transit of material.

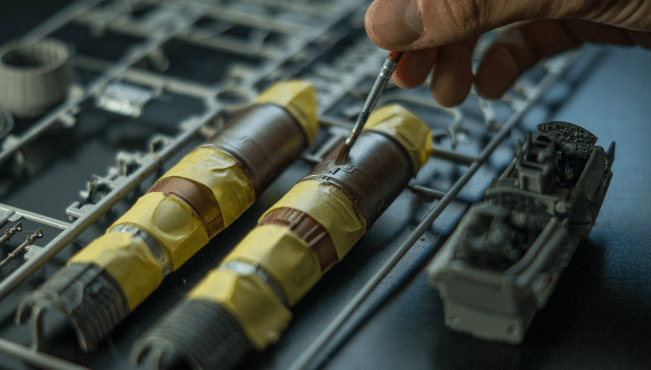

Putting the beads as a necklace has always been a crucial task. At IAC, a team of skilled technicians ensure proper assembly and fitting of various components to ensure that they are now ready for shipment to respective project locations. During this process they also ensure that the product is quality checked.

Tailor made machines have been installed in the helical forming area of IAC works to manufacture Armor rods & retaining rods of diverse sizes as per the project requirements.

IAC possess an in-house galvanizing capacity of 10,000 Metric Tons per annum. The planted is operated with least manpower and is semi- automated. The Zinc bath temperature is automatically controlled thus reducing the dross generated. We are able to adhere to galvanising thickness from 50-250 microns as per client requirement. Routine check of products is...

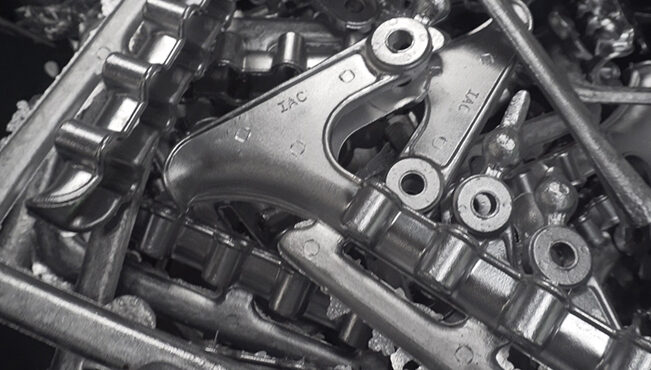

IAC maintains a reliable pool of manufacturers for its forging requirements. These units work as hands of the company delivering the required products with quality and within agreed timelines. IAC as the ‘principle” has the leverage to accelerate production of forging in these units.

Injection moulding machines help in manufacturing of Plastics items. Like, End cap, IPC, Wedge of ABC tension, REC suspension etc.

A more traditional form where liquid molten aluminium alloy of desired composition is poured into a die. The self- weight of the alloy helps the molten liquid to take its desired shape. This process is now superseded by a much-improved technique of pressure die casting which removes even small traces of air voids in the...

CNC pipe bending machines help in manufacturing of corona/interference reduction/protection rings of various configurations. Polishing or buffing of these rings are then carried out to remove any sharp edges on the surface thereby minimising the corona effect.

A cousin of traditional welding for ferrous items, this welding is performed at very high temperatures with special welding electrodes for aluminium alloy pipes and tubes mainly used for rings, dead end clamps, T-Connectors and various other components. This process requires trained/qualified welders.