High-voltage power lines snaking across vast landscapes or discreetly lining our streets are a familiar sight. But have you ever stopped to consider the silent partners that keep these lines aloft, ensuring the uninterrupted flow of electricity?

This unsung hero is pole line hardware – a diverse collection of components that play a critical role in the safe and efficient transmission and distribution of electricity. IAC Electrical, a pole line hardware manufacturer India manufactures pole line hardware and accessories and fittings.

The Essential Toolkit: What Makes Up Pole Line Hardware?

Pole line hardware encompasses a wide range of products, each with a specific function. Here’s a breakdown of some key players:

- Conductor Support:

- Insulators: These electrical barriers prevent current from flowing to the pole, keeping linemen safe and ensuring proper circuit operation. They come in various types, from disc insulators for distribution lines to high-strength suspension insulators for transmission lines.

- Crossarms: These horizontal structures, typically made of wood or steel, are secured to the pole and act as a platform for insulators and conductors.

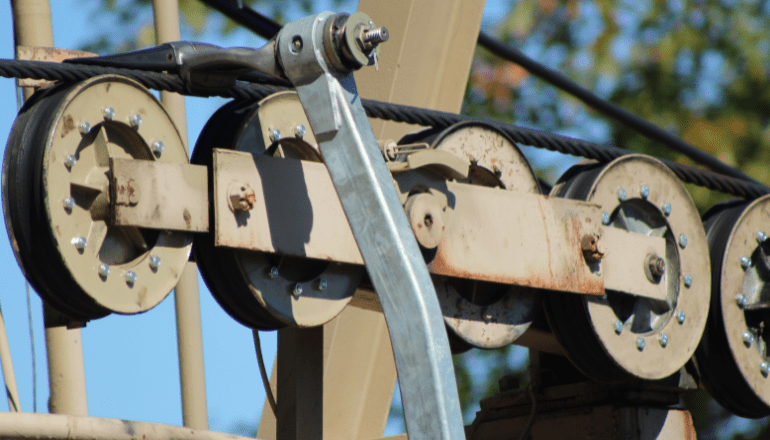

- Hardware: Clamps, bolts, and connectors of various shapes and sizes secure conductors to insulators and cross arms.

- Pole Stability:

- Guy Wire and Hardware: Guy wires are steel cables that extend from the pole to anchors in the ground, providing additional stability against wind, ice, and other environmental stresses. Guy clamps, thimbles, and turnbuckles are essential for proper tensioning and anchoring of these wires.

- Braces: In high-stress areas or for corner poles, braces made of steel or wood provide additional support to the pole itself.

- Safety and Grounding:

- Grounding Hardware: Ground rods and clamps ensure a low-resistance path for any stray current, minimizing the risk of electrical shock.

- Lightning Arrestors: These devices divert lightning strikes away from the conductors and safely to the ground.

Material Matters: Durability and Performance

The choice of material for pole line hardware is crucial. Here are some common options:

- High-Strength Steel: Offers excellent strength and load-bearing capacity for transmission lines and high-stress applications.

- Aluminum: Lightweight and corrosion-resistant, aluminum is a popular choice for distribution lines and applications where weight is a concern.

- Composite Materials: Fiberglass-reinforced polymers are increasingly used for insulators due to their high strength-to-weight ratio and excellent electrical insulating properties.

Beyond the Basics: Specialized Hardware

The world of pole-line hardware extends beyond the core components. Here are some additional specialized items:

- Cutouts and Fuses: These devices interrupt current flow in case of faults or overloads, protecting transformers and other equipment.

- Dead-End Hardware: Used at the terminations of lines to anchor conductors and prevent them from pulling out.

- Streetlight Brackets: These specialized arms attach luminaires to poles, providing illumination for streets and public spaces.

Ensuring Safety and Reliability: Standards and Regulations

Pole line hardware plays a critical role in public safety and power grid reliability. Stringent industry standards and regulations govern the design, manufacture, testing, and installation of this equipment. Following these guidelines ensures the hardware can withstand the demanding electrical and environmental conditions it faces.

Conclusion: The Invisible Backbone of Power Delivery

The next time you see power lines, take a moment to appreciate the unsung heroes – the pole line hardware. These seemingly simple components are meticulously designed and engineered to ensure the safe and reliable delivery of electricity to our homes, businesses, and communities.

From towering transmission lines to streetlights illuminating our paths, IAC Electrical produces pole line hardware fittings the invisible backbone of the power grid, silently working to keep our world electrified.