Advanced Facilities

The Company owns state-of-the-art manufacturing units spread across 150,000 sq. ft. and equipped with some of the latest machinery. We have transformed ourselves into a process-driven organisation. This has helped us to channel our resources and abstain from waste. The positive margins generated through a reduction in wastages and cost overruns are passed on to our customers.

Fabrication

Key manufacturing process enhanced with CNC machines for precision drilling and plasma cutting applied to various activities.

Our machining process, including CNC Turret Lathe, ensures precise product shaping and dimensions, saving time.

VMC, our in-house CNC machine, efficiently produces casting dies, ensuring timely order execution.

CNC pipe bending machines manufacture corona/interference reduction rings, followed by polishing to minimize corona effect.

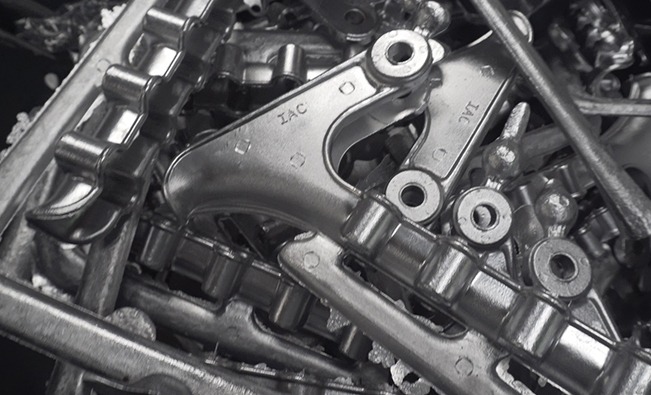

Aluminium Die Casting

Aluminium Die Casting is one of the most important and critical processes in hardware manufacturing.

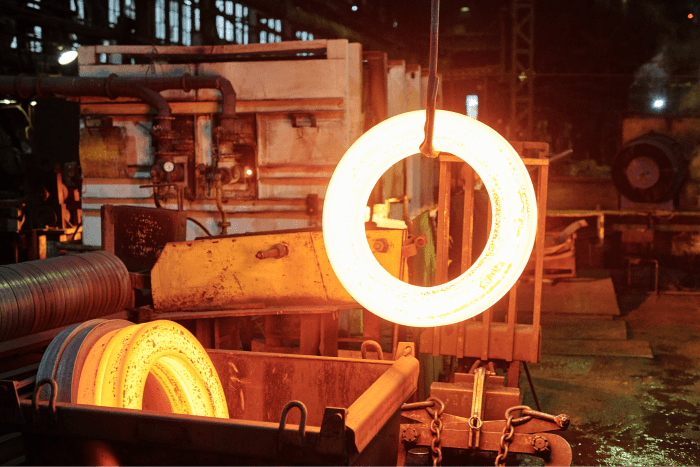

Gravity Die Casting

Molten aluminium alloy is poured into a die to shape products, later replaced by pressure die casting for better results.

Pressure Die Casting

PDC employs modern pressure techniques for efficient, high-quality alloy production, resulting in homogenous products, demanding expert skills.

Other Facilities

The factory prioritises safety with regular drills and designated areas. It also maintains ERP for material traceability and assigns responsibilities to process owners.

IAC maintains a network of reliable manufacturers for its forging needs, ensuring quality and on-time delivery. This allows IAC to expedite production in these units.

IAC’s in-house galvanizing facility boasts 10,000 Metric Tons annual capacity, offering precision galvanizing from 50-250 microns, all monitored for quality assurance.

Custom machines in the helical forming area of IAC create armor rods & retaining rods for various project needs.

At IAC, skilled technicians expertly assemble and quality-check components for shipment to project locations, streamlining the bead necklace process.

IAC products receive quality packing for safe transport, including sea-worthy packing for exports.

If you have any questions or need help, feel free to contact with our team.

506, Central Plaza, 2/6, Sarat Bose Road, Kolkata- 700020. India.

If you have any questions or need help, feel free to contact with our team.

506, Central Plaza, 2/6, Sarat Bose Road, Kolkata- 700020. India.

©2024 IAC Electricals, All Rights Reserved

Created by Meraqi Digital