Ever wondered what keeps the lights on and your devices humming without a hitch? The answer lies in the often-overlooked components known as connectors. These small yet crucial devices play an essential role in electrical systems, ensuring that power flows seamlessly from one element to another while maintaining safety standards.

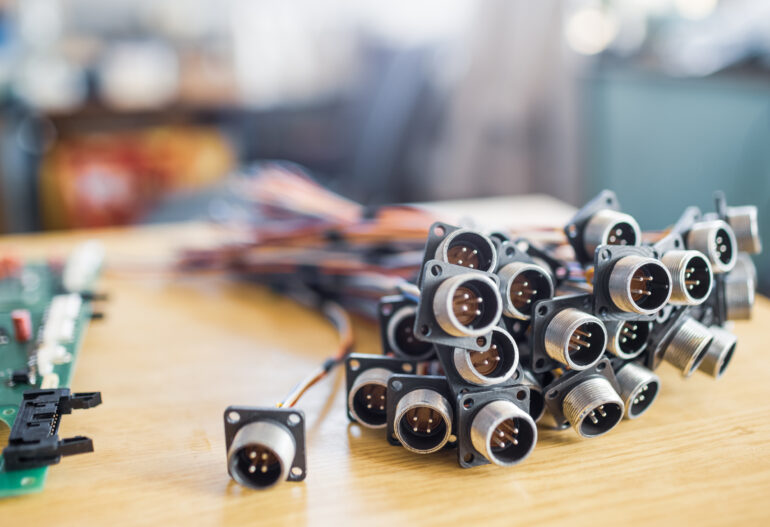

Connectors in power systems are designed to join electrical circuits, allowing for the transfer of electrical energy between different parts of a system. They come in various forms, including plugs, sockets, terminals, and junctions, each tailored for specific applications. The integrity of these connections is vital; poorly designed or damaged connectors can lead to overheating, short circuits, and even electrical fires.

In this blog of IAC Electricals, we are diving deep into the fascinating world of electrical connectors to discover the secret behind the functional electrical system. Let’s begin.

The Significant Role of Connectors in Electrical System

Understanding the importance of connectors in power systems is key to appreciating how they contribute to overall electrical safety. They play a crucial role in maintaining the flow of electricity while preventing overheating, short circuits, and even electrical fires. Here are several ways ab cable connectors play a critical role in ensuring that our electrical systems operate safely.

Prevention of Overheating

One of the primary functions of connectors is to provide secure and stable electrical connections that can handle the required current without overheating. When connectors are improperly fitted or degraded, they can create resistance in the circuit. This resistance generates heat, which can lead to insulation breakdown and pose fire risks. High-quality connectors are engineered to minimize resistance and maintain optimal conductivity, significantly reducing the risk of overheating.

Many modern connectors incorporate design features that enhance their thermal performance. This includes heat sinks or ventilation slots that help dissipate heat more effectively during operation. Assessing the importance of connectors in power systems, it is crucial to conduct regular inspections to keep the chances of overheating at bay. Checking for signs of wear, corrosion, or loose connections can help identify potential issues before they escalate into serious hazards.

Ensuring Reliable Connections

In any power system, reliability is the key. That is why the installation of the clamps connectors is necessary. Connectors in reality withstand environmental factors such as moisture, dust, and temperature fluctuations without compromising their performance. High-quality connectors undergo rigorous testing to ensure they can handle mechanical stress and environmental challenges over time. This includes vibration testing, thermal cycling, and salt spray tests to simulate real-world conditions.

Regularly checking connections for signs of wear or damage is essential. Loose connections can lead to intermittent failures, which may not only disrupt operations but also pose safety risks. So, to keep the inflow of electricity intact, investment in the connectors is a must-have action.

Facilitating Grounding and Bonding

Effective grounding is crucial for electrical safety, and connectors play a significant role in this process. Grounding connectors provide a path for fault currents to safely dissipate into the ground, preventing electric shock and equipment damage during faults.

Properly installed grounding systems utilize connectors specifically designed for grounding applications. The connectors in power systems ensure a low-resistance path to the ground, which is vital during fault conditions. However, Adherence to local electrical codes regarding grounding practices is essential for safety.

Compliance with Safety Standards

Using connectors that comply with established safety standards is vital and this practice aids in minimizing the risks associated with electrical installations. Organizations like the International Electrotechnical Commission and Underwriters Laboratories provide guidelines that manufacturers must follow when designing connectors. These standards cover aspects like thermal performance, mechanical strength, and electrical ratings.

When selecting connectors for your projects, look for products with proper documentation indicating compliance with relevant safety standards. This not only assures quality but also enhances overall system safety.

Protection Against Shock Hazards

Nowadays, most of the connectors are designed with safety features such as insulation and protective casings that prevent accidental contact with live parts. Quality connectors often have robust insulation materials that prevent accidental contact with conductive parts. This is especially important for outdoor or industrial applications where moisture and dust can compromise safety. So, investment in top-notch connectors is always the wisest decision for the project owners and managers.

Closing Thoughts

Connectors may be small components within a larger electrical system, but their role in ensuring electrical safety is substantial. Installation of the connectors in power systems is beneficial in every way. Understanding the significance of these components empowers us all to appreciate the intricate web of safety that keeps our modern lives powered up. To know more about the installation of connectors for complete electrical safety in both residential and commercial premises, connect with IAC Electricals, one of the most reputed clamps and connectors manufacturers in India.